Preethi Hard Anodized Induction Base Outer Lid Pressure Cooker 3 Litres

Preethi Hard Anodized Induction Base Outer Lid Pressure Cooker 3 Litres

Couldn't load pickup availability

- Do not use the coupon for pickup from courier.

- For orders outside India — prepaid only.

Quality Tests

|

|

|

|

|

|---|---|---|---|

|

840 hours Endurance test to ensure product durability. |

The hard anodized pressure cooker is carefully tested through 50,000 cycles to maintain its resistance to peeling and ensure long-lasting reliability. |

3000 cycles of Lid lock & unlock Test: Ensures the smooth functioning of the lid lock and unlock mechanism. |

Tests the durability and lifespan of the handles by subjecting them to 15,000 cycles of fatigue testing. |

Preethi Advantage

|

|

|

|

|

|---|---|---|---|

|

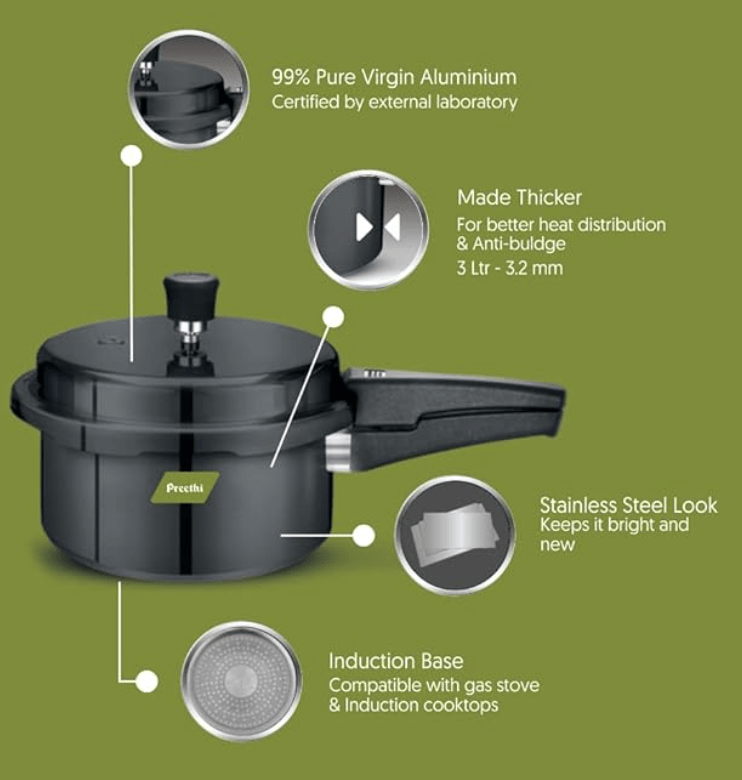

Made from virgin Aluminum sourced from No.1 manufacturer Hindalco. |

Enhanced Durability with 45 Micron Inner and 60 Micron Outer Coating Thickness. |

3L Hard anodized Comes with 3.2mm thickness which leads to uniform heat distribution and avoids food burn at the bottom. |

Virgin nitrile gasket offers better elasticity and safety. voids transfer of odour, colour, taste to the Cooked Food. |

|

|

|

|

|

|---|---|---|---|

|

SS 304 Food Grade stainless steel is used in all food contact area to ensure no food contamination. |

Specially Designed Handles with Flame Protector with double screws for durability. |

Seamless Lid Operation with a Reverse Locking System. |

All Preethi pressure cookers are ISI and ISO approved, guaranteeing quality and performance. |

Safety Mechanism

|

|

|

|

|

|---|---|---|---|

|

It is made to perfect precision and operates when the inside pressure reaches 1kg/sq.cm. and whistles, which are loud and clear. |

If the Vent Tube gets blocked and the weight valve does not function, a portion of the gasket is pushed out through a slot ( GRVS) in the lid. |

Once GRVS is activated, excess steam will be safely released through the top hole of the pressure cooker. |

The Metallic safety plug comes into operation, when excess pressure is built inside Pressure cooker. It contains a Bismuth alloy that melts to let out the steam. |